Springs

The Group is capable of producing various types of springs used in watchmaking. It is one of the few suppliers capable of producing the spring barrel which is the heart of the spring barrel, a watch’s energy module.

The Group has expertise in all materials that are used in the production of watchmaking springs, in particular:

- NIVAFLEX®, a multiphase alloy, which is a completely non-magnetic material with high energy potential, exceptional fatigue strength and excellent corrosion resistance.

- Générale Ressorts has filed patents for BIOFLEX®, an innovative material used for mainsprings. BIOFLEX® is a multiphase alloy free of cobalt, nickel and beryllium. It conforms to various standards, including REACH. BIOFLEX® is a unique, patented alloy which:

- reduces energy loss between 0 and 24 hours to increase chronometric stability,

- increases the spring’s fatigue strength,

- increases the number of turns, and thereby the power reserve.

Development – prototyping and manufacturing of barrel springs and other movements for the fine watchmaking, industrial and medical fields. Usage, laminating, stamping and moulding of very high quality alloys such as stainless steel, Bioflex and Nivaflex.

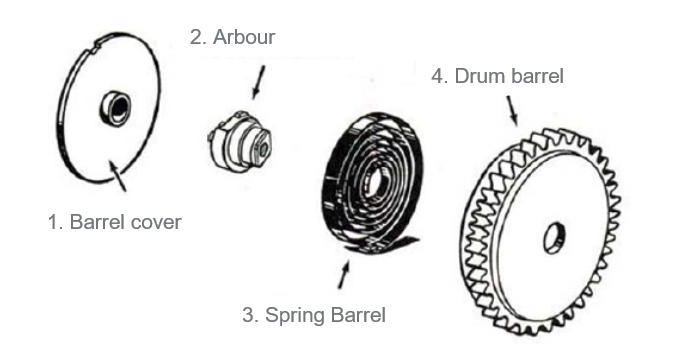

A watch’s energy module (complete spring barrel) generally consists of the following pieces:

- The barrel cover which is used as a closure along with the drum barrel, in which the contents of the barrel spring are located

- The arbour, on which is fixed the spring barrel

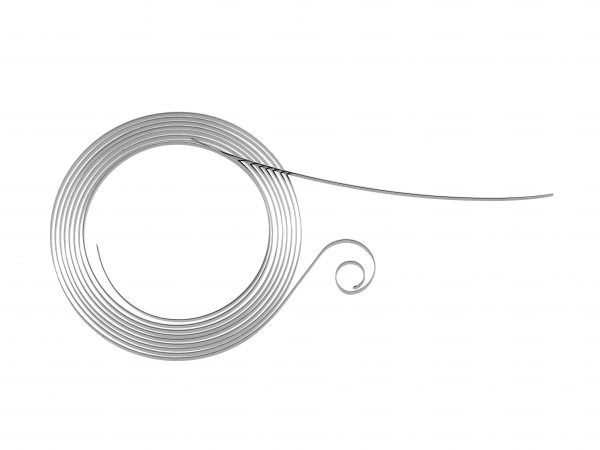

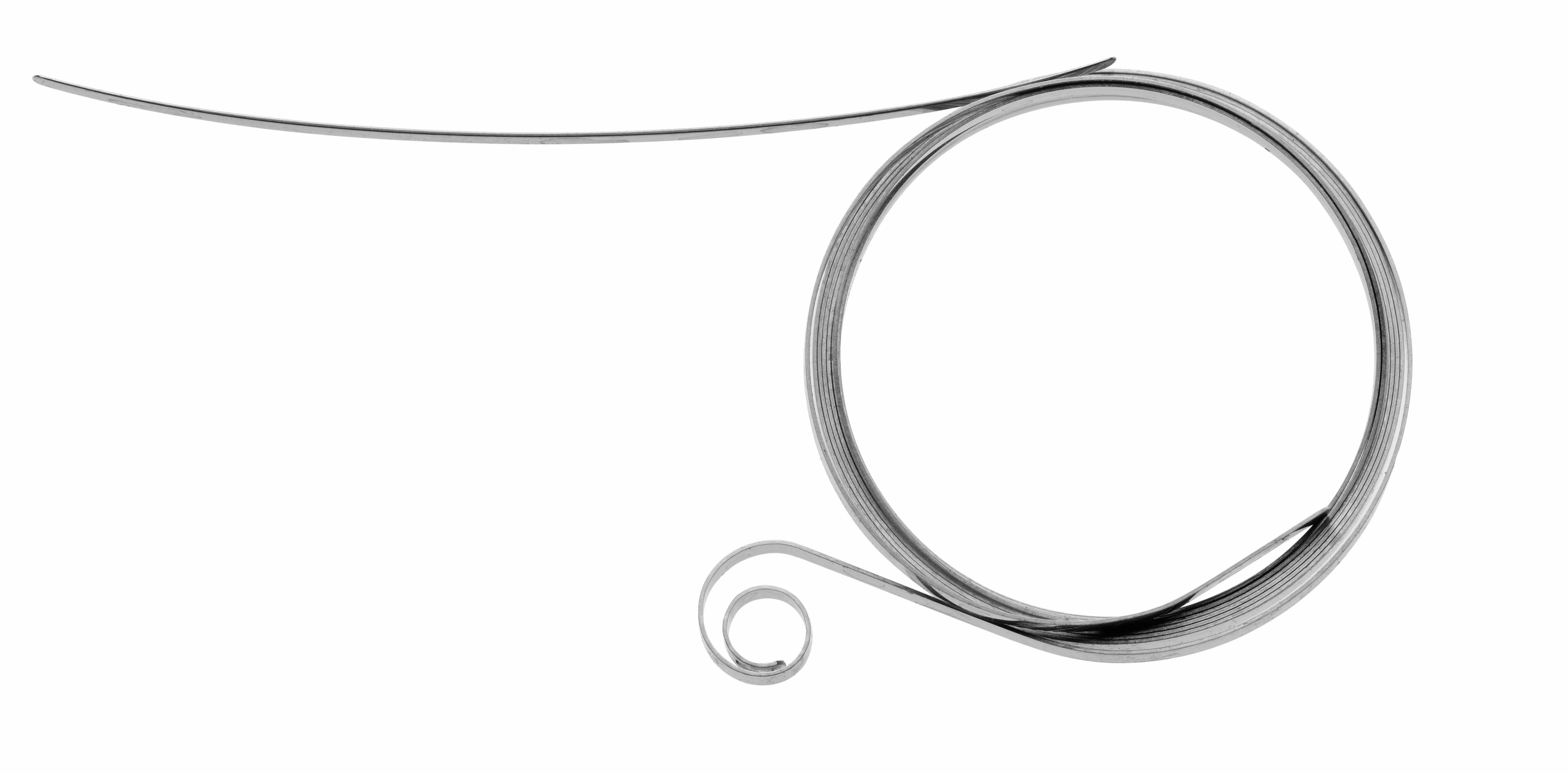

- The barrel spring, which enables the conservation of energy when it is stretched and to release it when it is unwinding. Most of the time it is made of a metal ribbon made of steel wound inside a wheel

- The drum barrel is what enables the transmission of energy to the wheel when the barrel spring unwinds itself

For all requests you can contact Jean-Michel Uhl at GÉNÉRALE RESSORTS, under the following email :