Diener AG Precision Machining

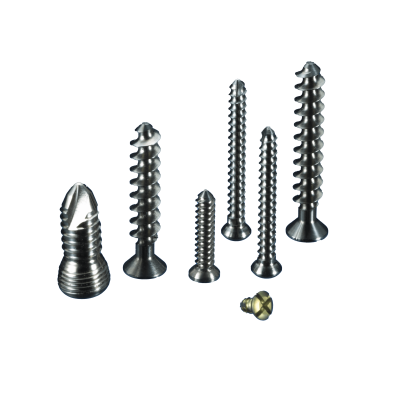

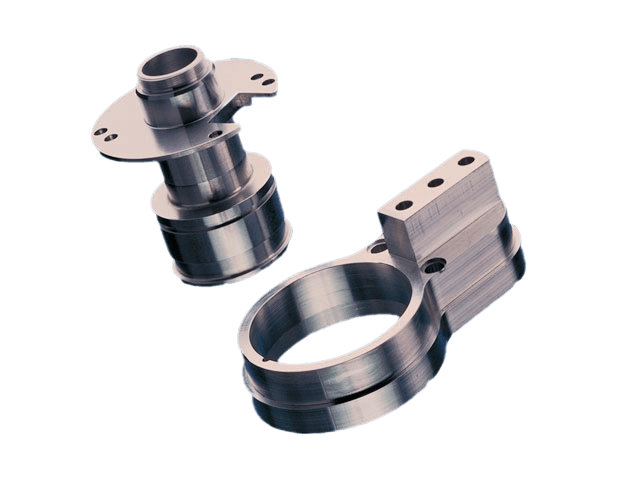

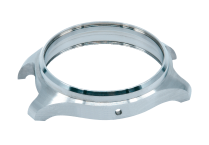

Diener AG Precision Machining is heavily involved in the Medtech industry, producing high-quality mechanical components and specialized subassemblies for medical devices (implants and instruments).

Expertise

The company produces with state-of-the-art equipment and measuring devices a wide range of precision components in titanium, stainless steel, PEEK, aluminum alloys and plastics. Diener AG Precision Machining operates a class 7 clean-room according to the latest technology.

The company is certified with ISO 13485:2016.

The core competencies are CNC-milling, CNC-turning, different micro-blasting treatments, assembly, cleaning, clean room services, and packaging among others.

Its production tool is based on:

- Over 50 CNC lathes

- Over 20 3-, 4- and 5-axis CNC vertical machining centers

- Micro blasting treatments

- Several laser marking stations

- Assembling lines

- Washing and packaging in class 7 clean-room

Materials

- Titanium

- Stainless steels

- PEEK

- Cr-Co alloys

- Aluminum alloys

- Plastic material

Markets served

Products & Services

- Turning

- Milling

- Assembly

- Laser marking

- Deburring

- Clean Room Operations

- Packaging

- Labelling

Management

Downloads

Diener AG Precision Machining

Stationsstrasse 66

8424 Embrach, Switzerland

+41 (0)44 866 33 33

info@diener-ag.com

www.diener-ag.com

Stationsstrasse 66

8424 Embrach, Switzerland

+41 (0)44 866 33 33

info@diener-ag.com

www.diener-ag.com